Modular Framing & Prefabrication

Prefabricated modules regularly increase profit margins and decrease expenses, by realizing maximum quality output and continuity and reduced completion times on site.

With our 41x41x2.5 mm channels, all parts fit consistently, providing the maximum number of supports and framing applications with the minimum amount of labor and materials.

Prefab Module solutions will increase project efficiency and eliminate the time spent waiting for materials. Even the most fast-tracked projects can be better managed and timely completed.

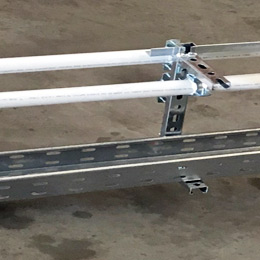

Conduit Trapeze Supports

Trapeze hangers are the most commonly used supporting method in the industry. Applications are most often used to support metal, plastic, aluminum, and fiberglass conduit and tray systems.

Due to the ever-increasing site costs and deadlines, we offer prefabricated supports including pipe clamps and fixing materials in one kit.

Service which helps in:

- Reduced Site Installation.

- Reduces Site Storage.

- The bracketry can be designed to Client’s Specifications.

- Factory Assembled Ensuring Accuracy And Consistency In Quality.

- Bracket Loadings & Pull Out Tests Can Be Undertaken.

Bracketry can also be supplied as a kit of parts.

Modular Assembling

C channels can be cut to specific lengths and bundled as entire assemblies for quick and easy field installation.

We can assemble a combination of Cantilever arms with brackets including strut-nuts and all requested fixing material as a total package. metal, plastic, aluminum, and fiberglass conduit and tray systems.

We can offer all the brackets and fittings we produce pre-assembled with strut nuts of your requirement.

ESM can offer a wide range of expertise and services to supply custom solutions to suit the modular framing & assembling needs of any project.